In addition to classical machining technologies, we focus on the use of modern NC and CNC technologies. Our manufacturing capabilities range from material forming and cutting, through chip machining, welding to final finishing.

ASL-Tech s.r.o.

metal production for world brands

PRODUCTION TECHNOLOGIES

For a better insight into our production capabilities, we offer a basic overview of key manufacturing technologies. In case of specific requirements, we will ensure cooperative production. Our advantage is the ability to process complex design documentation using modern 3D CAD systems.

Material forming

| Type | ||

|---|---|---|

| Hydraulic Press CDM 80 | 80 ton | |

| Hydraulic Press-Brake ESPE CTO 250-A | 250 ton | L=4000 mm |

Material cutting

| Type | diameter in mm | |

|---|---|---|

| Material cutting with band saw | 400 | |

| Plasma and autogenous cutting VANAD Proxima | 300 - 2000x6000 | |

| Laser cutting VANAD Kompakt laser 3kW | 15 - 1500x3000 |

Turning

| Type | diameter above the bearing in mm | length in mm |

|---|---|---|

| The turning SV18, AZL5000 | 380 - 1000 | L=3000 |

| CK7135A CNC | L=400 |

Drilling

| Type | diameter in mm | dimension table in mm |

|---|---|---|

| The drill press | 50 | 250x300 - 400x500 |

| VO50, VS32, RF22/A |

Milling

| Type | clamping surface in mm | table motion in mm |

|---|---|---|

| MILL1040 CNC | 1000x400 | 1000x400x500 |

| FCQV63 CNC | 2200x630 | 1500x630x630 |

| FSS80 CNC | 3000x800 | 3000x800x1000 |

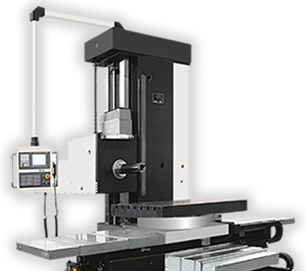

Boring

| Type | diameter in mm | dimension table in mm |

|---|---|---|

| Machining Center WFQ 80 NCA-01 | 130 | 1600x1000x800 |

| Machining Center WFQ 80 NCA-02 | 130 | 1600x1000x800 |

| Machining Center CNC FSQC 80-01 | 130 | 1250x900x850 |

| Machining Center CNC FSQC 80-02 | 130 | 1250x900x850 |

Welding equipment

| Type | voltage | protective atmosphere |

|---|---|---|

| Welding semi ForMIG | 160-315A | CO2, AR, Argomix |

| 400FWS, 459FWS, 452.1FW | ||

| Welding Positioner | load capacity 1250kg | |

| 17SSP301, 17SSP630 | ||

| LORCH MicorMig 500 | ||

| LORCH S5 Pulse XT | ||

| LORCH TR 3 | ||

| CRP RH 20-06-W robot with accessories |

Surface treatment

| Type |

|---|

| Sandblasting, Painting wet |

Heat treatment / annealing

| Type | Internal dimensions | Max. heating temperature |

| HTT 40 | 2700 x 1500 x 1400 | 700 stC |